Binkos Everlasting Inkstand

| Categories | Ink Bottle |

| Material | Glass |

| Markings | See Narrative |

| Origin | England |

| Date or Era | circa 1885 |

| Measuring | 2” x 2” x 1 ¾” high |

This is a notable Victorian mechanical inkwell known as the Binkos Everlasting Inkstand, an invention designed to solve the perennial problem of ink evaporation and sediment buildup.

Description & Construction

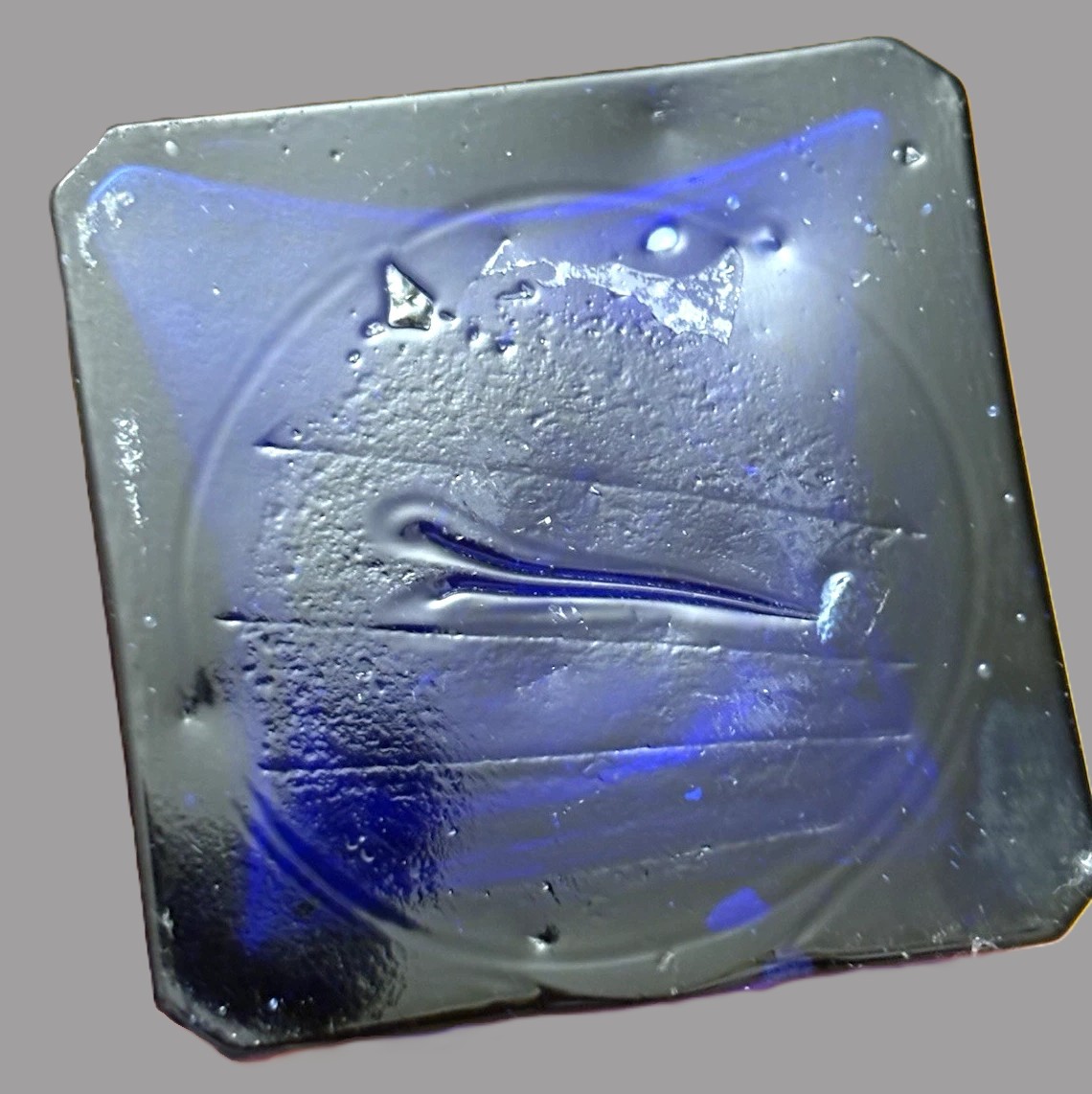

- Dimensions: Approximately 2 inches square by 1 ¾ inches tall.

- Material: The body and the exterior of the lid are made of deep cobalt blue glass.

- The Lid: It features a screw-on glass cap with an inset brass or bronze medallion. The medallion bears the name “BINKOS EVERLASTING INKSTAND” and the initials “HB” in a shield.

- Maker’s Mark: In smaller text, it is marked “STOCKER’S PATT LONDON”, referring to the patent held by Frederick Stocker.

Historical Background: Binko & Stocker

This inkstand was the product of a partnership between Henry Binko and Frederick Stocker in London.

- The Patent: The design was patented in the mid-1880s (specifically around 1884–1886).

- “Everlasting” Concept: The marketing term “Everlasting” referred to the inkwell’s ability to keep ink fluid usable for extended periods. The airtight seal prevented the water in the ink from evaporating, which otherwise caused the ink to thicken into a useless sludge or “mud”.

- The Partnership: Binko was an inventor of various electrical and telegraphic apparatuses, and Stocker was a merchant; together they marketed these specialized glass desk accessories to the growing Victorian middle class.

Manufacturing Process Indicators

The physical details on this piece provide a clear “biography” of how it was made:

- Ground Glass Opening: You can see that the rim of the well and the interior of the glass lid have a frosted, matte texture. This was achieved through a “ground-in” process where the lid and body were literally ground against each other with an abrasive paste. After the bottle was blown and cooled, an artisan used a spinning abrasive wheel to grind the two surfaces against each other until they fit perfectly This ensured a perfectly matched, airtight vacuum seal that prevented ink from drying out.

- The Pontil Mark: The underside of the base shows a rough, circular scar known as a pontil mark. This proves the inkwell was hand-blown. A glassmaker would have blown the molten blue glass into a square mold, then used a “pontil rod” to hold the base while finishing the neck and threads. When the rod was snapped off, it left that distinctive mark.

- Mold-Blown Shape: The square shape shows it was blown into a two-part metal mold, but the presence of the pontil mark distinguishes it from the fully automated, machine-made glass that became common later in the 20th century.

Approximate Age

- Circa 1885.

- The use of a pontil mark on a molded piece and the specific London patent date place this squarely in the late Victorian era.

Sold for $54 in December 2025

Content disclaimer. The information posted is the owner’s best knowledge and may not have been vetted by the SOIC. We welcome comments, corrections, and additions, working to make our website information comprehensive and accurate.

Join the Society of Inkwell Collectors (SOIC) – it’s free!

Founded in 1981 as a non-profit organization,

we are documenting inkwells (and accessories).

We’re here to help and inform!