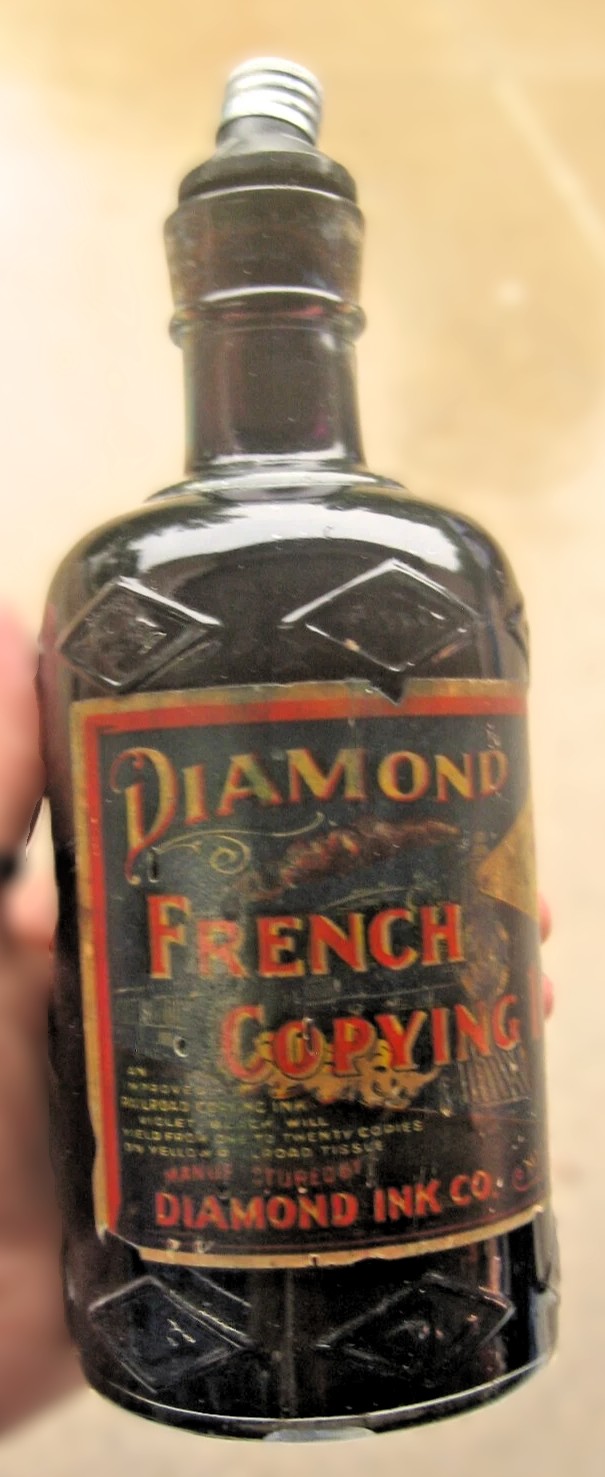

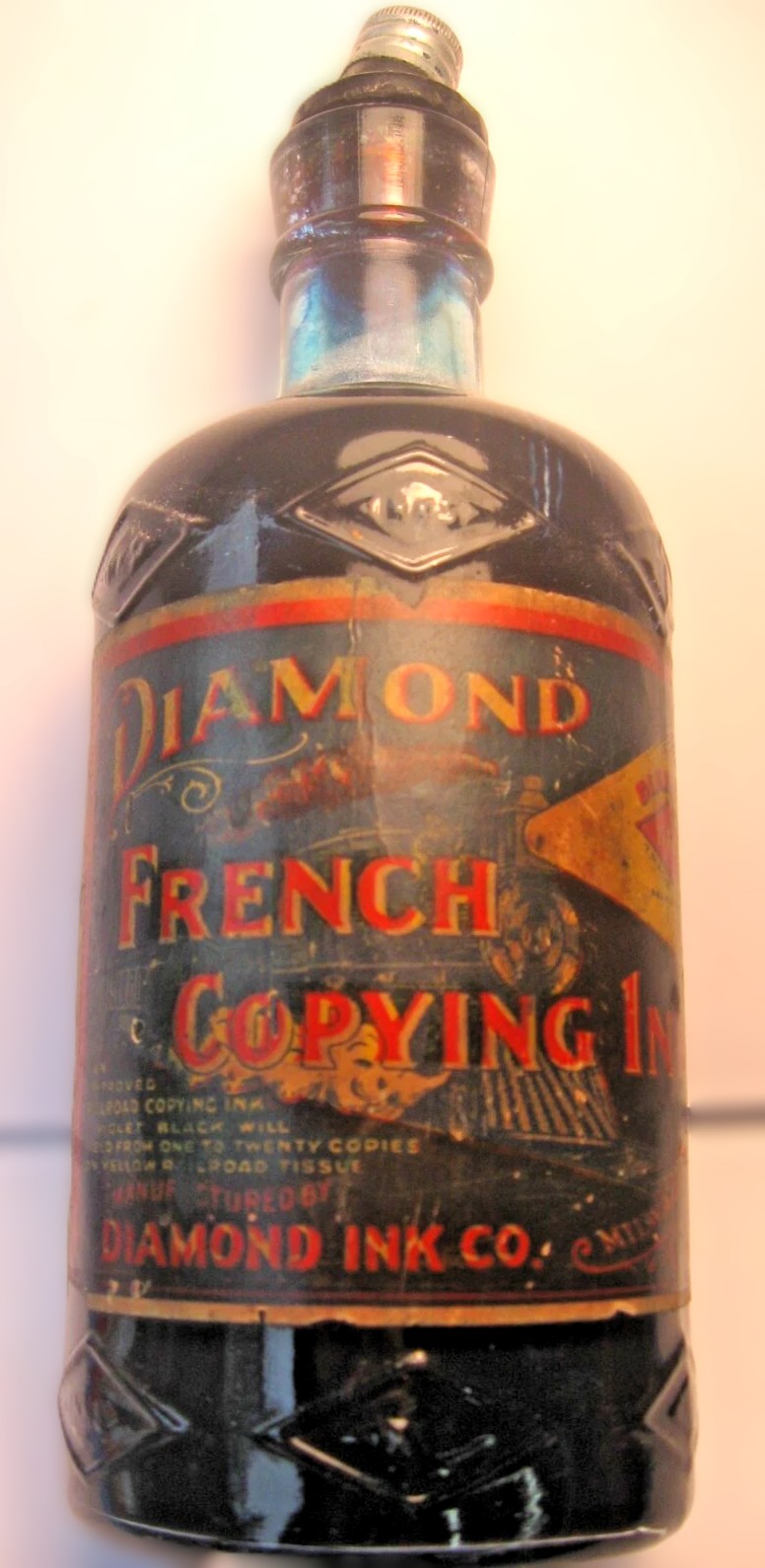

Diamond Ink Co. Bottle

| Categories | Ink Bottle |

| Material | Glass |

| Markings | See Narrative |

| Manufacturer | Diamond Ink Co. |

| Origin | United States |

| Date or Era | circa 1900 |

| Measuring | 3” diameter; 8 ½” high |

Diamond Ink Co. Bottle Description

This is a glass ink bottle from the Diamond Ink Co., Milwaukee, Wisconsin, notable for still retaining its original paper label and a distinctive metal cap and pouring mechanism.

- Bottle Design: The bottle is made of clear glass. Its body is embossed with multiple diamond shapes in a geometric pattern, visually reinforcing the company’s “Diamond” name.

- Pouring Mechanism & Stopper: The bottle features a metal spout or pouring mechanism attached to its neck. This mechanism screws onto the bottle. It’s designed to facilitate controlled pouring of ink into an inkwell, minimizing spills and mess. A separate, well-fitted stopper is inserted into the spout’s opening to seal the ink, preventing evaporation and contamination when not in use. The metal cap covering the stopper also features a diamond design, echoing the bottle’s embossing and the company’s branding.

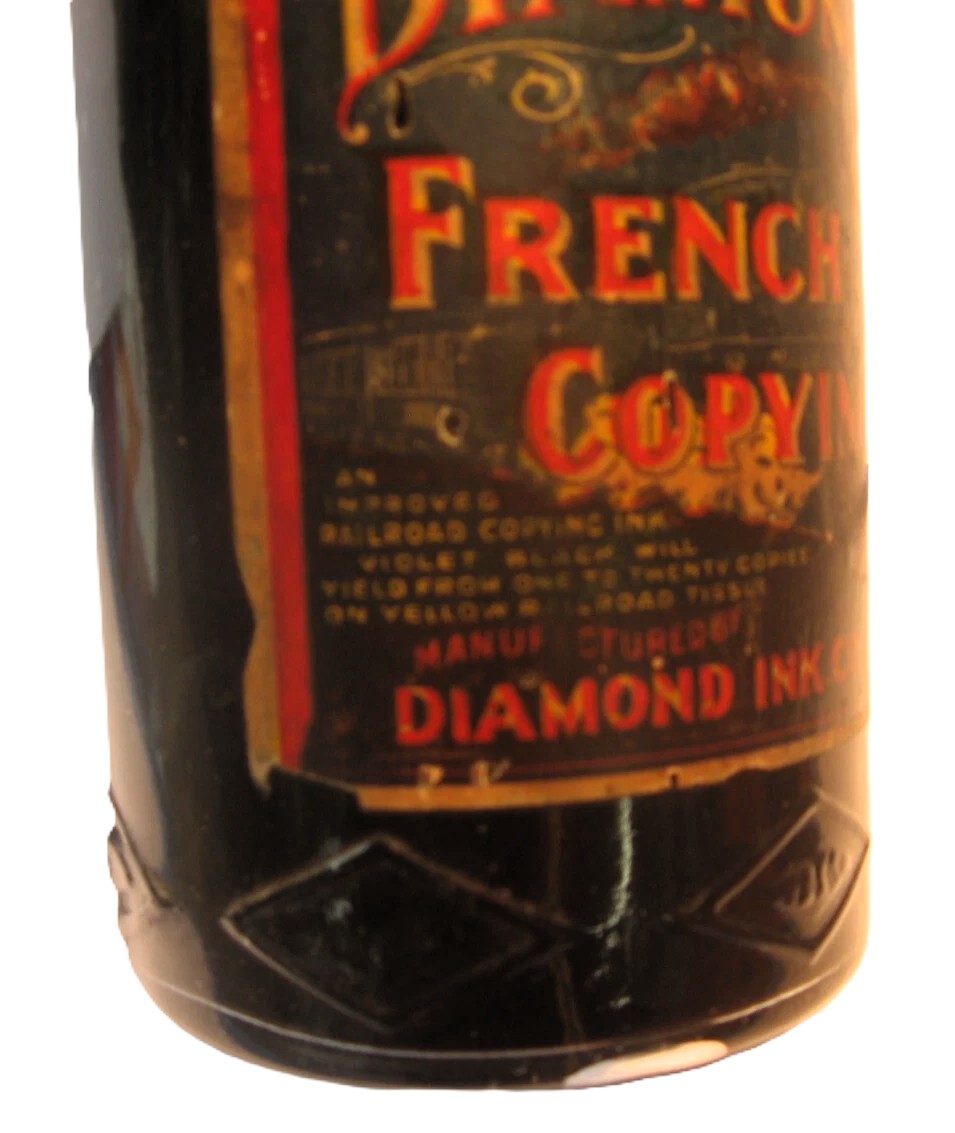

- Original Label: The bottle retains its original paper label:

- “Diamond French Copying Ink”

- “Manufactured by Diamond Ink Co. Milwaukee Wis”

- “An approved railroad copying ink, violet black, will yield from one to twenty copies on yellow railroad tissue.”

The Process of “Copying” Ink

“Copying ink,” also known as press ink or copying fluid, was a staple in offices from the mid-19th century through the early to mid-20th century, before the advent of carbon paper and later photocopiers.

The Copying Process (Letterpress Copying)

The “one to twenty copies” refers to the output from a process called letterpress copying (or wet-copying). Here’s how it worked:

- Special Ink: The key was the ink itself. Copying inks like “Diamond French Copying Ink” were formulated with a higher concentration of dye and often contained hygroscopic agents (like sugar or glycerin) that kept the ink moist and prevented it from drying too quickly. This allowed the ink to remain soluble for a longer period after writing. The “violet black” color was a common and effective shade for copying inks.

- Writing the Original: A letter or document was written using this special copying ink.

- Damping the Tissue Paper: A thin sheet of tissue paper (often called “copying tissue”) was lightly dampened, usually with a damp cloth or a special damping book.

- Pressing: The damp tissue paper was then placed directly over the freshly written (or even slightly older) original document. This sandwich of original document and damp tissue was then inserted into a copying press (a large, screw-operated press).

- Transfer: The pressure from the press would transfer a mirror image of the original writing onto the tissue paper, as the moisture from the tissue re-dissolved a portion of the ink and pulled it onto the tissue’s surface.

- Yielding Copies: By using progressively less damp sheets of tissue paper, or by re-dampening and pressing, multiple copies could be made from a single original. The phrase “one to twenty copies” indicates the ink’s high quality and concentration, allowing for numerous legible duplicates from one original writing. These copies were typically translucent and read from the reverse side or by holding them up to the light.

Why Yellow Railroad Tissue?

- Thinness and Translucency: Copying tissue had to be very thin and somewhat translucent to allow for effective ink transfer and to be read easily (often from the reverse side, as the copy was a mirror image).

- Yellow Color: The yellow color was a common industry standard or a specific preference for the railroad industry. It might have been chosen for contrast, readability in specific lighting conditions, or simply to differentiate railroad copies from other general office copies. It could also have been related to the specific type of paper stock that worked best with the copying process for that industry.

Why the Railroad? Was this ink made specifically for the railroad industry?

Yes, this ink was specifically marketed and likely formulated for the railroad industry.

- Massive Documentation Needs: Railroads in the 19th and early 20th centuries were vast, complex organizations. They generated an immense amount of paperwork: waybills, freight manifests, passenger lists, telegrams, operational orders, correspondence, payrolls, and more.

- Need for Duplicates: It was crucial to have multiple copies of these documents for various purposes:

- Sending copies to different departments or stations.

- Keeping central records.

- Providing copies to customers or freight recipients.

- Archiving for legal and auditing purposes.

- “Approved Railroad Copying Ink”: This phrase on the label is significant. It implies that the ink met specific quality standards or even received an official endorsement from a railroad association or major railway company. Railroads, given the critical nature of their operations, would have demanded reliable and high-quality ink for their records. This approval would have been a major selling point for Diamond Ink Co.

How Old is This Bottle?

Given that it’s “copying ink” (which fell out of widespread use with carbon paper and photocopiers) and explicitly “railroad copying ink,” this bottle likely dates from the:

- Late 19th century to early 20th century.

- A range of 1880s to 1920s would be a very reasonable estimate. The “French Copying Ink” name also suggests a period when French chemical advancements in dyes were highly regarded.

History of the Diamond Ink Co.

The Diamond Ink Co. was based in Milwaukee, Wisconsin. Like many ink manufacturers of the era, they catered to the enormous demand for writing and copying inks in burgeoning American industry and offices.

- Rise in the Late 19th/Early 20th Century: The company would have flourished during the late 1800s and early 1900s, a period of massive growth in industry, commerce, and government, all of which required vast quantities of ink for record-keeping and communication.

- Specialization: As seen with this bottle, they likely specialized in certain types of inks, such as copying inks for specific industries like railroads, which had particular needs for durable and replicable documents.

- Decline: The company, like most traditional ink manufacturers focusing on copying inks, would have faced significant challenges and likely ceased operations or diversified as technology shifted to carbon paper, typewriters, and eventually photocopiers and computers after the mid-20th century. Information on smaller, specialized ink companies from this period can be scarce, as they were often absorbed by larger entities or simply went out of business as their primary product lines became obsolete.

Sold for $198 in June 2025

Content disclaimer. The information posted is the owner’s best knowledge and may not have been vetted by the SOIC. We welcome comments, corrections, and additions, working to make our website information comprehensive and accurate.

Join the Society of Inkwell Collectors (SOIC) – it’s free!

Founded in 1981 as a non-profit organization,

we are documenting inkwells (and accessories).

We’re here to help and inform!